I say it's a pattern cutting course; in fact this is now combined with garment construction which I think is a good idea. It means, though, that there is less design and less draping than there might have been and more making up. This suits me, I confess, as my needs are more about developing the skills appropriate to make a wedding dress!

Next week is the mid term break so tonight we were handing in our portfolios to have them looked at to make sure we were going in the right direction.

So far, we have some draping, some TR pattern cutting and some flat pattern manipulation of bodices, skirts and sleeves. We have also made up samples for gathering, construction of inset corner (this being particularly useful for some potential wedding dress styles especially as also used in godet construction) and plackets. I have finally understood the difference between 'gathering' and 'easing'!

Tonight (Thursday 22 October), we started to make up a shirt/blouse. This would utilise skills in collar insertion, placket making, yoke insertion and of course ultimately button holes.

|

| A preview! Front |

We are using a size 12 (UK) standard block so of course the finished shirt wouldn't fit me in a month of Sundays!

In class, we managed to cut out the pattern and then the fabric. I inserted the darts and double folded over the front. Our tutor R didn't want us to try to finish the blouse at home but she wanted us to try to insert the yoke using the same clean insertion method she had and add the patch pocket.

R chose my pieces to demonstrate what we had to do with the yoke pieces. Unfortunately, I had only cut one and so R borrowed one from Sarah. Trouble is I had to give this back to Sarah and I hope that I can work out what to do - it seemed pretty complicated. R said she was using a standard shirt yoke construction method. I wonder, however, if this is what some refer to as the 'burrito method' as we ended up with what looked like a burrito!

So after my bridge weekend away, which starts tomorrow, I have 10 days or so to complete the blouse to the necessary stage and make some other replacement samples.

Up to date now

I drafted those earlier paragraphs a week ago. Today I did my homework for return to class next week, well at least part of my homework - I have quite a number of images to gather and some research to do.

I don't sleep well while I'm away from home. Instead of counting sheep, I've been going through the possible steps for the clean yoke insertion! I couldn't find it in my books, surprisingly but I did a bit of internet search and came up with a Craftsy post on the 'clean yoke insertion'. Later, they say this is also known by some as the burrito method, so my feeling was correct. My tutor is very traditional and working in the UK this probably isn't a term used while she was training. I didn't use the Craftsy method exactly as I remembered and had written down some of the details my tutor gave as she demonstrated.

Anyway, bear with me. I took photos of my process today and I'm going to post them here as part of my future portfolio and to remind me of the process.

Clean finish method of yoke insertion:

I started with a back, two fronts and two yoke pieces - these are referred to as yoke and yoke facing.

I had originally forgotten to cut out the yoke facing; luckily, I had a piece of fabric big enough to allow me to do that now. My front pieces has the centre fronts turned in, pressed and pinned, though later I removed these pins for ease of manoeuvrability. I apologise in advance for white fabric against grey - though that was better than against the white of my sewing machine table where my camera completely refused to play ball!

|

| 1. Pin yoke to back of blouse along straight line, right sides together |

|

| 2. Now pin yoke to front at shoulders. Again, right sides facing. |

|

| 4. Same as above but opened out |

|

| 5. The pieces are now sewn together using a 1 cm seam in this case |

|

| 6. Looking at it from the outside, ie right side. I pressed the seam allowances towards the yoke before the next step. |

|

| 7. Now the magic starts! I have carefully rolled up fronts towards yoke and back towards yoke. |

|

| 8. The fronts and back are rolled up to yoke; yoke and yoke facing reach together over them and pinned |

|

| 10. Stitched burrito |

|

| 12. Well, all out - terribly crushed. This is an inside view. |

|

| This is an attempt to show inside and outside at the same time. It's not yet pressed. |

|

| 13. Yoke has now been pressed. |

|

| View of front of blouse. |

- Firstly, this wasn't nearly as bad as I'd feared.

- Secondly, the stitching is trying to come away at the edges. I used a big stitch length for ease of unpicking if needed. There is a lot of pressure on these edge stitches while turning through, so I should have reinforced the ends or finished off better.

- My turning out might have been easier if I'd rolled the fabric differently

- To be careful with which side of yoke facing is stitched - I found it counter-intuitive when I was going to attach along back edge (wrong side to right side there) but easier to envisage on the shoulders as the seam lay in an easier direction.

- I don't think the cutting in class was as careful as it could have been. It's important to cut out carefully, mark all notches and match these while sewing.

Patch pocket

I'm not doing a step by step photo journal here - to be honest, I didn't even think of it at the time!!

Method:

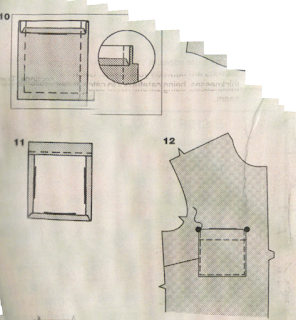

The patch pocket was cut out in class using a paper pattern we had cut from the cardboard templates (not blocks as these had seam allowances on them). 1 cm turnovers again. I cm at the top and then 2 cm. The position of the second turn was marked by snipping.

I chose to make a cardboard template with the seam allowances removed as that allowed me to fold the edges over the cardboard and press.

|

| Excuse the distortion of perspective! The sides are actually parallel. I couldn't get a better photo tonight but will do better for my portfolio |

|

| Scanned from an old pattern instruction sheet |

10.

Press under 1cm on upper edge of pocket.

Turn upper edge to OUTSIDE along fold line, forming

facing. Stitch along seam line on raw edges as far as the main pocket. Trim seam allowance in the facing

area to 6 mm

11.Turn

corners RIGHT side out, turning facing to the WRONG side; press, pressing under

raw edges along template edge.

Stitch facing close to inner edge.

12.

On OUTSIDE, pin pocket to left front. I didn't have markings on the blouse

front so used the front edges to ensure my pocket was straight and guesstimated

from pictures of shirts blouses. Personally I wouldn't put on a pocket for me - disastrous in this position!! Stitch close to side and lower edges.

I tried the shirt to this point on Missy, my small model.

|

| Front view - the side seams are not stitched |

|

| View f yoke - the side seams are not stitched |

|

| Pocket close up. |

Model renovation and correct sizing

On another note, my little model is falling apart and I need to modify to use for Helen as I don't want to spend a lot buying a new one. I think this one should do as although Helen is 6' tall, her length is largely in her legs, which are endless! I've lengthened the model as much as possible - the overall height is tiny but the body is not too bad, I hope at least.. My tutor said then to pad the model out to Helen's sizes, using a toile I've already fitted. I have a few problems with this. Sure, although I expanded to the correct size, the proportions are not the same so I will shrink down again. I need to fill in the gaps where the adjustment mechanism is. Missy's cover is tatty and I bought a new one but can't yet get it on! Missy's shoulders are rather large, I think. David thought it might be a good idea to build up with mouldable high density foam. Anyone have any experience of this?

I'm planning to start some sewing that's not course related tomorrow. I'm looking forward to that.

Anne